What is Low-Volume Manufacturing

Low Volume Manufacturing is a typical process in industry, it's expected as the effective solution to solve the technical issues between the development phase and mass production. Low volume manufacturing can be used to test the structure design and predicts all the risks and fixes them before production. This helps to reduce the investment risk and faster accessing to market. Furthermore, in some cases low volume offers direct end-user manufacturing for complex parts, which only need small batch production, from 1 piece to 1000 pieces.

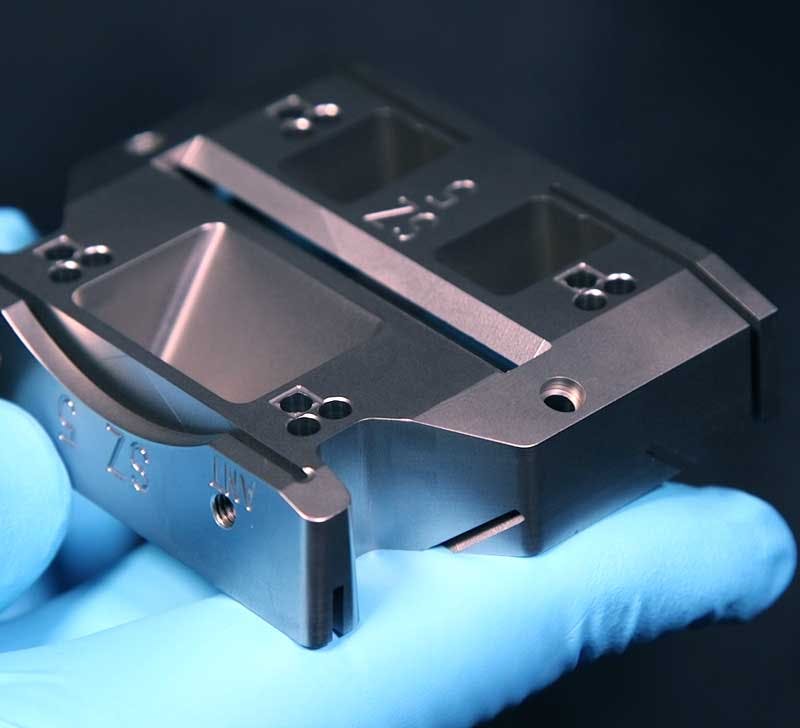

3D metal printing and cnc prototyping is the common processes to create low volume quantity in practice. Exzellenc has lots of experience dealing with our customers for metal parts manufacturing with harsh requirements.

Low volume manufacturing in metal additive manufacturing

One of the applications in metal additive manufacturing is to produce the metal parts, whose material are expensive, such as titanium, nickel, silver. The conventional subtractive process, like cnc machining, will enormously increase the cost because of the material wasting. There is another condition that the metal material is extremely hard such as tool steel, conventionally they are difficult to be machined. In these cases, the metal additive manufacturing is the best solution to produce the metal parts in low volume manufacturing.

Low volume CNC machining

Unlike the huge-scale production CNC machining provides another method for small batch production without minimum order. CNC prototyping is getting more popular in various industry with its advantages. On one hand, it offers a possibility to create part with complex geometries which difficult to be done by tooling. 5-axis machining is highly recommended in this case since its high cutting efficiency in any point of parts. On the other hand, cnc machining can also produce the part up to 100k pieces with automatic process.

Now let's dig it out what are the advantages of low volume manufacturing.

1. Low volume offers bridge production

Before the products move into full scale production, it's recommendation to start with bridge production to test the response of market. You can increase the output at any time you want when the products are getting positive response from market. At the point of long-term view low volume production is a good way for saving money.

2. Reduce tooling cost with low volume manufacturing

When going to the high-volume production to produce for a new product, you need molds to form the different parts. Take a consideration, the molds are very expensive, is it worth to make a hug investment on the new products without clear market feedback. In addition, the tool lifecycle is limited for large scale production, when surpassing the quantity, you need to pay extra money for new tool making.

The low volume manufacturing allows you avoiding the tool making and quick accessing into market with high quality products using modern cnc machining or metal 3d printing. The processes have no limit on the quantity, even only one part. For small company who want to get into market with not so much cost on production, low volume is a best choice. With the flexible production and growing up on demand, you can greatly cut down the complete investment, and more returns in meantime.

3. Low volume allows flexible design iteration

Before the product design or part design finally confirmed, there are still some modifications, which can be discovered with low volume production. Direct going tool making or mass production will possibly occur some unforeseeable problems that bring extra huge cost. The engineering tests the manufacturability and modify the design when issues come out.

4. Low volume shortens the lead times

Fastly accessing to market is essential to strength competitiveness. To shorten the lead time of new products it's useful to produce with low volume manufacturing, like 3D metal AM process, delivering end-user products in fast way. So, you can gather feedbacks in short time from customers, which will give clearer for you next decision. This is the ideal way to reduce the inventory with solid supply chain that will save more time for delivering the massive products quick to market.

Working with Exzellenc

Since Exzellenc's team is focusing on complex cnc machining and 3D metal additive manufacturing, we have many projects with low volume to do. If you are looking for a skillful engineering for your metal parts production, Exzellenc is the right one for your projects.