Metal AM Materials:Aluminum and Copper powders

The metal powders are currently getting increasing attention in the metal AM supply chain. One the one hand, there has been a noticeable rise in material requirements as a result of the steady adoption of metal additive manufacturing. On the other hand, industrial applications that have improved performance, better properties, and new metal compositions speed up the process of material research. Powder manufacturing and material research are the two most important variables for supporting the future growth of the metal 3D printing sector.

1. Aluminum alloy powder with high fluidity

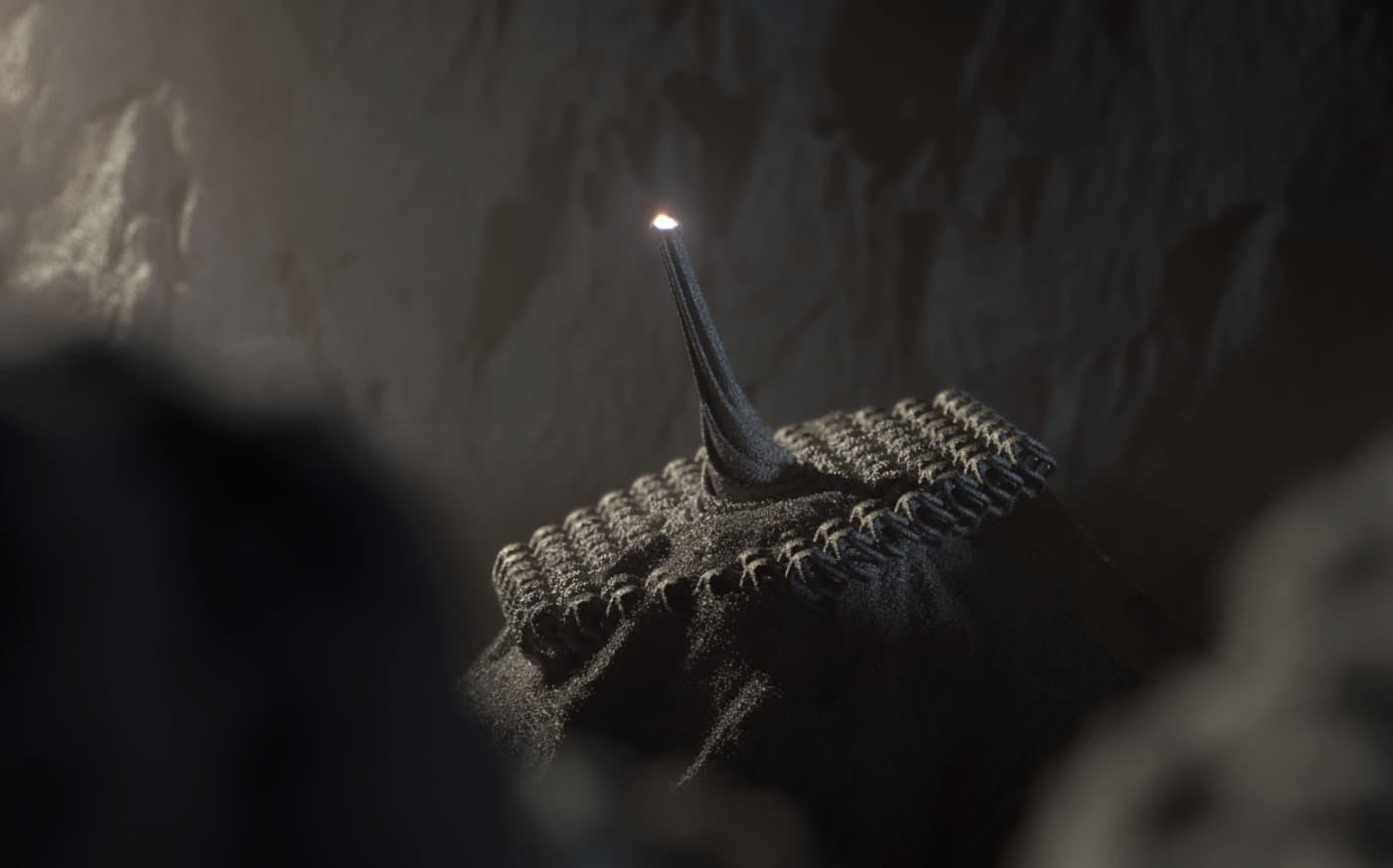

Since aluminium alloy has a light density and is difficult to attain high fluidity on its own, its application in metal AM has raises concerns about its fluidity. Additionally, forming control of aluminium alloy powder during printing is more challenging than it is for other alloys. Although the common powder bed technique does not currently require that the raw metal powders have Hall fluidity prior to use, application and milling manufacturers are working to increase the fluidity condition of aluminium alloy powder in order to improve powder uniformity and process adaptability. High powder sphericity (>95%), good fluidity (15-53 m Hall flow rate approximately 70s), high bulk density (1.45g/cm3), and hall powder rate control are all characteristics of high fluidity aluminium alloy powder products. It has been used in batches in the automotive, aerospace, and other areas during the last three years. Research on the production of aluminium alloy powder with additive manufacturing will prove to be critically significant in the future. Different powder properties are needed for specific alloy additive manufacturing techniques, such the binder spraying approach that will enable widespread use of aluminium alloys in the automotive industry. The utilization of high-flow aluminium alloy powders in metal AM has huge potential in the future.

2. Pure copper powder with high conductivity

Compared with copper alloys, the advantages of pure copper powder are its electrical and thermal conductivity, but the drawback is its low absorption for conventional 1064nm lasers, making it difficult to achieve densification. The current solution is to use short-wavelength lasers, such as TRUMPF's 515nm green laser equipment, and the other is to increase the laser power. No matter what type of equipment and process, to obtain high density, high electrical and thermal conductivity of copper printed parts, which require the raw material powder with high purity. In addition, powder properties, such as even particle distribution, good fluidity, and high bulk density, are required for better densification. According to experiments, copper powder has a bulk density greater than 4.8g/cm3, a fluidity of within 15s/50g, and a conductivity greater than 95%IACS, all of which are beneficial for increasing purity and high sphericity of the copper powder as well as for electrical and heat conductivity.

3. AlCu: high-strength & heat-resistant

High-strength aluminum alloys are an urgent demand for metal additive manufacturing of aluminum alloy materials. As additive manufacturing turns to industrial practices, the properties of AlSi alloys can no longer meet the requirements. However, because traditional high-strength aluminum alloys are not fully suitable for laser forming, the problem of composition design and improvement of additive-manufactured high-strength aluminum alloys arises. At present, there are several types of improved components for additive manufacturing of high-strength aluminum, such as Scalmalloy, a patented product of Airbus, AlMnScZr from Monash University in Australia, and 7A77.60L from HRL in the United States. The manufacturing of high-strength aluminum materials is still single. In traditional industrial manufacturing, aluminum alloy is the most widely used non-ferrous metal material, and there are many types of aluminum alloys with different strength, stiffness, hardness, heat resistance and corrosion resistance. In the future, additively manufactured aluminum alloy materials will also form different systems based on comprehensive performance requirements, not just one dimension of strength. The Exzellenc team continues to pay attention to the development of high-strength, heat-resistant and corrosion-resistant materials in high-strength aluminum. In 2021, it will cooperate with the non-ferrous metal material manufacturing laboratory to develop AlCu-based high-strength heat-resistant aluminum alloy products suitable for additive manufacturing. The tensile strength is greater than 400MPa, and it is expected to become an important new product in the additive manufacturing of high-strength aluminum alloys. High-strength, high-toughness aluminum alloys have broad application prospects in aerospace vehicle manufacturing, automotive lightweight manufacturing and other industries.

4. High strength and high thermal conductivity copper alloy powders for mold industry

In the mold industry, copper alloys are also a widely used material. At present, the conformal waterway printing of mold steel materials has been widely used, and the copper alloy conformal waterway mold with higher thermal conductivity will also have application potential in the future. SLM Solutions launched CuNi2SiCr for mold making in 2019. This material is a heat-treatable hardened alloy with a balanced combination of high strength and thermal and electrical conductivity. The alloy includes nickel and silicon for high resistance to corrosion and wear resistance. The research shows that the powder properties and heat treatment process have regular effects on the strength, hardness and thermal conductivity of CuNi2SiCr, and the fluctuation is higher than that of other metals. Based on this, the composition of the CuNi2SiCr product was improved, and the corresponding heat treatment parameters were developed to stabilize the yield strength above 550Mpa, while maintaining the corresponding hardness and thermal conductivity, in order to meet the requirements of mold manufacturing.

conclustion

Metal powders are currently being updated and improved to fit the high demand in metal AM industry. A broader variety of new metal powder will be available in the nearly future, and even unique materials designed for particular 3D printing use. It's expected, multi-level researches on metal powder materials and ongoing cost reduction are helpful in boosting the advancement of metal additive manufacturing industry.